Qonic: accurate BIM

Qonic: accurate BIM

Quelle/Source: Qonic: accurate BIM - AEC Magazine

While BIM has changed the way architects work, it hasn’t necessarily benefitted all project participants equally. The lack of trust, and the need for different types of information to be included at different phases, has brought in new inefficiencies. New start-up Qonic aims to help.

In AEC Magazine over the last few years, we have looked at how BIM modellers were originally devel oped to automatically produce drawings, and therefore provide productivity savings. In isolation, in a utopia, this has been the case so long as you don’t edit them in a 2D drawing application like AutoCAD, as changes to the model will need to be manually edited again.

The idea of a single building model, on which all companies would collaborate has not come to fruition, with the standard practice being multiple models created by multiple project participants for different purposes.

This has led to the need for Common Data Environments (CDEs), complex file management and much duplicated effort. It also extends into fabrication, where detailed 1:1 models and drawings are created.

All these issues combined have left many in the industry pondering what comes next. And with a new generation of design tools, what functionality and capabilities will we need?

The flow of data from concept design to fabricated building is interrupted many times. Somehow, we need a system that can talk openly throughout the design and construction process.

The re-start-upNeuer Text

Startup Qonic is developing what it promises to be a unique take on ‘upscaling’ BIM, while taking it to the next level of accuracy, both in geometry and depth of data.

Based in Ghent, Belgium, there are a few familiar faces to be seen at its HQ. The co-founders – Erik De Keyser, Mark Van Den Bergh, Tiemen Strobbe , Tjerk Gauderis and Sander Scheiris – are all formerly from Bricsys (developer of BricsCAD). In some ways calling Qonic a start-up is a misnomer, as the group has worked together as a team for many years. This is a re-start-up and it has already grown to twenty people.

De Keyser has a long history in AEC software. He was an architect, got into software development, developed TriForma, which was licensed to Bentley Systems, and when that deal soured he formed Bricsys to develop BricsCAD, an AutoCAD clone that eventually outgrew that constraint and became a complete development platform for BIM, manufacturing and civil design in itself – all based on DWG. Finally, in 2018, De Keyser sold Bricsys to Hexagon and after spending a short amount of time there, he left.

Now free of BricsCAD, as well as the constraint of developing with a DWG envelope, the team has been able to start anew on a fresh, contemporary BIM engine. De Keyser has always used solid modelling in his applications to define 3D geometry – TriForma used Parasolid, BricsCAD used ACIS and now Qonic features a top secret new lightweight kernel of origins unknown, which has direct modelling capabilities and can handle NURBS.

This adherence to solid modelling is not unique (Vectorworks is also powered by Parasolid) but it’s exceptionally important to one of the vertical niches to which Qonic wants to appeal – those working with estimates of quantities.

As the majority of BIM models are inaccurately modelled, taking quantities off them has always been a problem and would lead to more work than was originally intended.

In a Qonic model, concrete volumes, for instance, will be accurate and details will be modelled and intelligently applied throughout a model at 1:1 accuracy. Qonic’s role is about beefing up the bits of BIM models that support downstream processes to alleviate the pressure on remodelling by sorting the problems earlier on in the golden thread.

Hybrid BIM

One of the key aims that this industry needs to address in the next five years is how design information flows from architect to fabricator.

Currently all BIM systems have been developed for a traditional workflow. And while there has been considerable investment in skills and software, for architects, MEP engineers and some structural engineers, the contractual endresults get squashed down to 2D drawings in PDF format.

As firms look to benefit from digital fabrication and off-site construction, Qonic looks to play a role as an intermediary system capable of understanding and absorbing traditional BIM files, at various levels of detail, together with highly accurate solid representations of parts to be manufactured, or materials to be procured for construction.

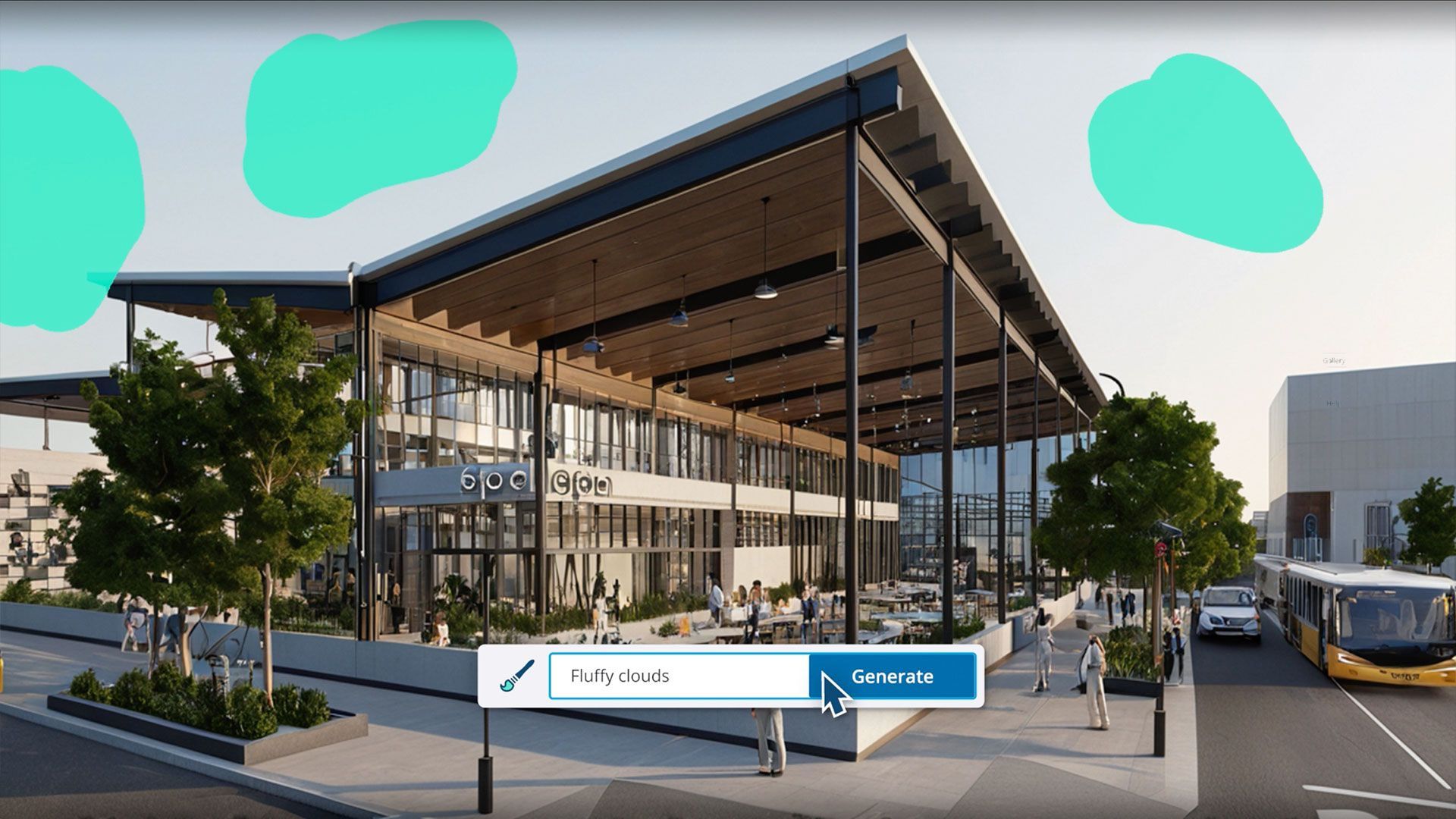

The development team is committed to utilising open standards and the demonstration we saw in Ghent, was heavily biased towards importing IFC models and displaying them in Qonic’s cloudbased viewer.

Many people are unaware that IFC now has the capability to capture and display high resolution geometry. Qonic parses the IFC and generates a solid model version of the data. This can be from one IFC or multiple contributed models.

Even when launching a multi-gigabyte dataset, it was very fast to move about the model and access the underlying BIM data. And this is still alpha code. The team has utilised streaming games technology to ensure that geometry closer to the point of view is full definition, while model data that is far away is rendered in lower detail. As one moves around the model it’s possible to see a slight shimmering of distant geometry, as the software streams in additional detail as it gets closer to the field of view.

Models are stored locally and shared via the cloud, the initial transaction taking the longest time and, from there on in, only the changes are sent. It’s possible to work offline and synchronise on demand, with the system tracking changes and keeping the history of edits.

Devil in the details

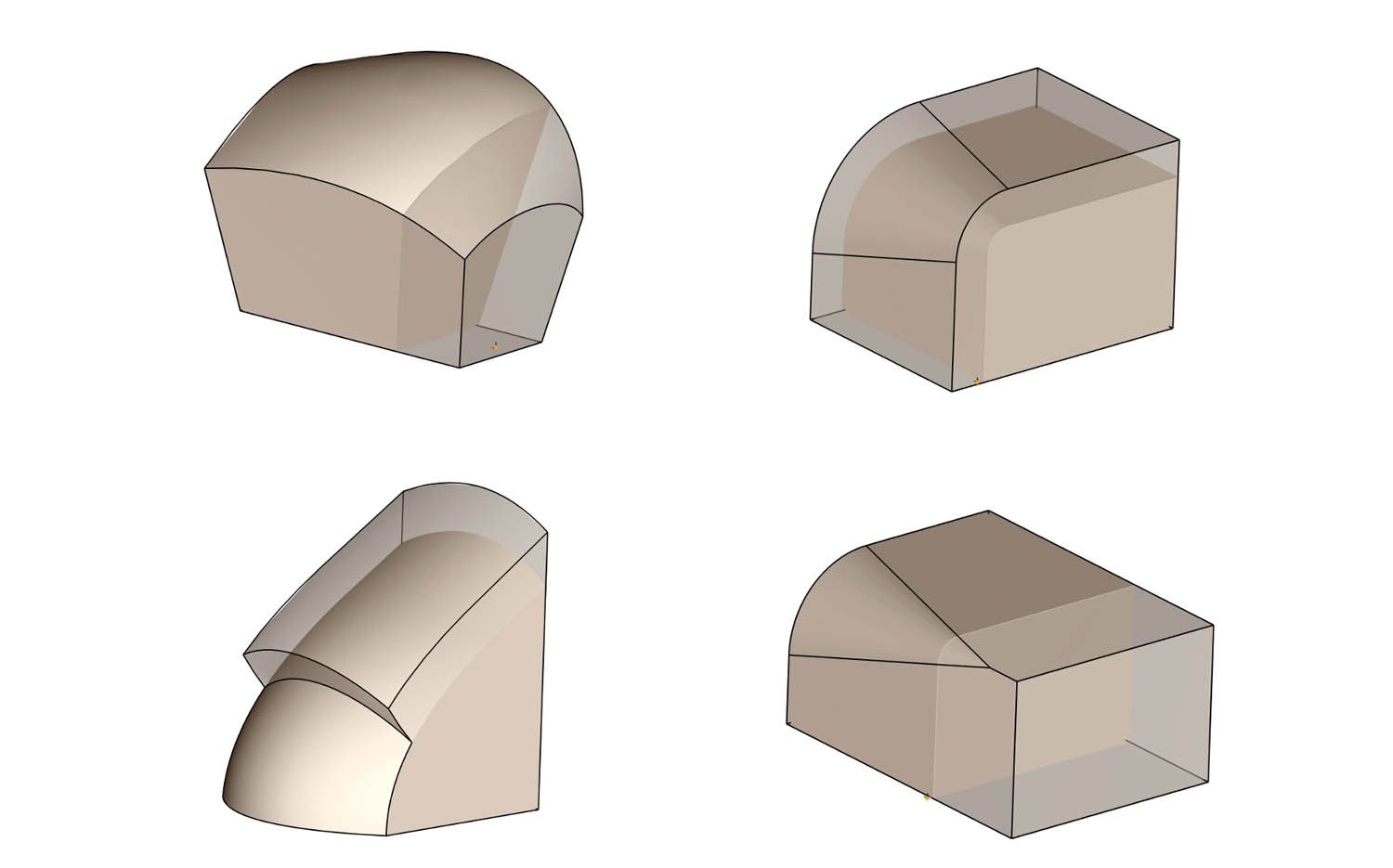

Viewing is the basic functionality. Qonic aims to drastically reduce errors by taking the strain out of performing tedious tasks which are error prone – tasks such as manually placing lintels for a specific type of window across an entire model.

If the window varies in size, then Qonic comes with a library of detailed parts which will find and replace the low detail windows in the model and adjust the lintel for each one. This will also apply to details such as sills, roof caps, interior finishes, wall composition for all spaces in the building. If using a spaces designation – e.g. for a hospital design – then the correct room fit out can be applied, or fire doors detailed. This is aimed at turbo charging the process of adding in details to benefit all stakeholders.

Neuer TextAll this means Qonic can be used as a tool to collate data from different systems, at different levels of detail. It benefits from automated detail generation throughout components. And because IFC is at the very heart of it, it can be exported and brought into any other IFC compatible applications. This is a lot more than your typical common data environment application. This is a design refinement tool.

The viewing app is very impressive, and comes with several smart filters to quickly isolate and see IFC classified groups, such as columns, beams, MEP etc. Every element contains material layers, so complex filters could be set to find columns made of a certain material. This works very much like hash tags and is very easy to use.

Qonic is cloud-based enabling collaboration, which here means sharing designs with colleagues and teams, or having access in the field. The viewer can be accessed on a web browser, on a mobile phone or on desktop. Having said that, some capabilities will be reserved for the desktop version, requiring local processing power for modelling etc.

Conclusion

Qonic isn’t like anything I’ve seen before. It seeks to address common problems that affect everyone in the industry for which there are no real solutions other than remodelling, redrawing. The level of detail that its database can hold demonstrates that it’s exceptionally performant.

To model to this level of detail would kill any of today’s BIM systems. This is the benefit of being able to start from scratch with a clean sheet and being able to use the latest technologies.

The team is adamant that it will keep the system open, with commitment to IFC at the core, together with APIs for open access.

Unfortunately, the application will not be out in beta until later this year. However, if you like what you’ve read here and are interested, the team have invited firms to get in touch by reaching out to them via LinkedIn.

Finally, one for the details folks – the name Qonic originates from a Ghent conical sweet delicacy, the Cuberdon. Unfortunately, the cone domain wasn’t available, which introduced the need for some creative thinking.